Sugar Industry Challenges in 2024: How ERP Systems Can Help?

Not as sweet as it used to be? The sugar industry is facing a multitude of challenges in FY 2024, from volatile market conditions to increasing pressure for sustainable practices. But fear not!

ERP systems can be a perfect solution to help you address challenges.

This blog explores the current landscape of the sugar industry and how ERP systems can help manufacturers navigate these challenging times.

Market Dynamics and Supply Chain Challenges in the Sugar Industry

- Current Market Conditions: Sugar prices around $0.22 per pound and concerns over supply shortages from major producing countries like India and Brazil pose significant challenges to industry players.

- Price Trends: Despite recent declines, sugar prices are expected to remain elevated compared to historical averages due to factors such as India's restrictions on sugar cane use in ethanol production and Brazil's record-breaking sugar exports.

- Brazil's Role and Future Challenges: Brazil plays a key role in the global sugar trade but may face challenges leading to a potential surplus in 2024 followed by a deficit in 2025. This delicate balance is influenced by global factors such as policy changes, pricing dynamics, and energy trends, especially in Brazil, where the allocation of sugar cane for ethanol production is under scrutiny.

Sugar Industry Challenges in 2024 and Beyond

- Economic Uncertainty and Agricultural Policies: The global economy's vulnerability and uncertain agricultural policies of trading partners and competitors contribute to increased volatility in the sugar industry, which heavily relies on exporting to the global market.

- Climate Change: The sugar industry faces more volatile business conditions due to climate change, affecting both production costs and the uncertain quantities of raw materials.

- Transition to a Low-Carbon Economy: Policies and measures promoting this transition, such as international trade measures and carbon taxation, increase the cost of operating sugar businesses, leading to adjustments in production costs.

- Sustainability Trends: Consumers and industries using sugar as a raw material increasingly prioritize environmental, social, and ethical issues, impacting the sugar industry's sustainability efforts.

ERP Can Be of Big Support!

ERP (Enterprise Resource Planning) systems can help manufacturers in the sugar industry stand strong against the challenges they face. By providing real-time data and insights, ERP systems enable manufacturers to make informed decisions regarding pricing, production, and supply chain management. This can help them navigate through market volatility and supply shortages more effectively. ERP systems also streamline operations, improve efficiency, and reduce costs, which is crucial in a high-priced and uncertain market environment. Additionally, ERP systems can support sustainability efforts by tracking and managing resources more efficiently, aligning with consumer and industry trends towards environmental and ethical considerations. Overall, ERP systems can enhance the resilience and competitiveness of sugar manufacturers in a challenging market landscape.

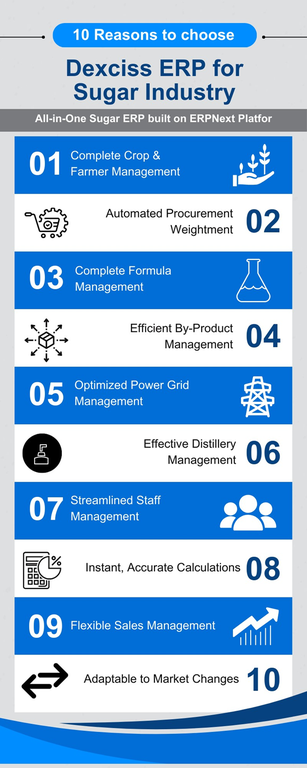

All-in-One ERP for Sugar Industry:

Dexciss ERP built on ERPNext Platform

Dexciss ERP offers a comprehensive suite of features specifically designed to address the sugar industry's unique challenges:

Crop & Farmer Management

- Benefit: Support farmer training and guide them through the sugarcane lifecycle with best practices, from pre-planting to harvest. Conduct and track farm surveys at regular intervals to help farmers acquire seeds/crops at subsidized prices.

- How it meets challenges: Helps sugar manufacturers ensure a stable and quality supply of raw materials, despite challenges like market volatility and supply shortages, by optimizing farming practices and enhancing farmer support.

Seamless Procurement with Automated Raw Material Weighment

- Benefit: Eliminates the need for weighment clerks at Gross & Tare, reduces manpower costs, and ensures error-free transactions. Monitored remotely through digital cameras for accuracy and speed.

- How it meets challenges: Addresses supply chain challenges by streamlining procurement processes, reducing costs, and ensuring accurate transactions, essential in a volatile market environment.

Complete Formula Management

- Benefit: Oversees the entire production process, from sourcing and cleaning sugarcane or beets to packaging. Maintains consistent quality and optimizes output with an auto-sizing feature for easy material substitution without compromising taste or accuracy.

- How it meets challenges: Helps sugar manufacturers maintain product quality and optimize production output, crucial in addressing challenges related to climate change and economic uncertainty affecting production costs and raw material quantities.

By-Product Management

- Benefit: Provides comprehensive management for by-products such as bagasse, molasses, ethanol, and distillery products, maximizing revenue streams.

- How it meets challenges: Helps sugar manufacturers maximize revenue and efficiency, addressing challenges related to economic uncertainty and sustainability trends by optimizing the use of by-products.

Power Grid Management

- Benefit: Streamlines operations for bagasse-powered plants or distillery units, optimizing power generation for sustainability and cost-effectiveness.

- How it meets challenges: Helps sugar manufacturers manage the transition to a low-carbon economy by optimizing energy usage and reducing operational costs, addressing challenges related to sustainability and economic uncertainty.

Distillery Management

- Benefit: Tracks inventory, optimizes production, ensures quality, and facilitates regulatory compliance for efficient operations.

- How it meets challenges: Helps sugar manufacturers manage operational challenges and regulatory requirements, addressing issues related to economic uncertainty and sustainability trends affecting production costs and processes.

Staff Management

- Benefit: Effectively manages workforce with shift scheduling, rotation tracking, and accurate payroll processing. Controls employee expenses like electricity usage for streamlined personnel management.

- How it meets challenges: Helps sugar manufacturers manage labor costs and efficiency, addressing challenges related to economic uncertainty and operational efficiency in a volatile market environment.

Instant yet Accurate Calculations

- Benefit: Supports management of raw materials with different conversion between units and reverse calculations for accurate tracking and future production planning.

- How it meets challenges: Helps sugar manufacturers optimize resource usage and production planning, addressing challenges related to economic uncertainty and climate change affecting production costs and raw material quantities.

Flexible Sales Management

- Benefit: Caters to both retail/distribution and deal-based sales processes, managing the complete sales cycle for timely deliveries and satisfied customers.

- How it meets challenges: Helps sugar manufacturers adapt to changing market conditions and customer demands, addressing challenges related to economic uncertainty and market volatility.

How long does it take to implement ERP software in a sugar manufacturing plant?

The time it takes to implement ERP software in a sugar manufacturing plant can vary depending on the complexity of the system and the size of the plant. However, with ERPNext's user-friendly interface and implementation support, sugar manufacturers can expect a relatively quick and smooth implementation process.

Get Best ERP Software for your Sugar Manufacturing Industry today!

Schedule a demo today to see how Dexciss ERP can transform your sugar manufacturing operations.

No comments yet. Login to start a new discussion Start a new discussion