Seamless integration.

Empowering flexibility. Admirable simplicity.

Admirable simplicity.

One solution

Integrate different departments for improved visibility and greater flexibility. Use end-to-end modules to meet your every business need.

Cloud deployment

Get accessibility to critical operations, real-time reports, and valuable functionalities like receiving products, QC, and more on your smartphone, on the go.

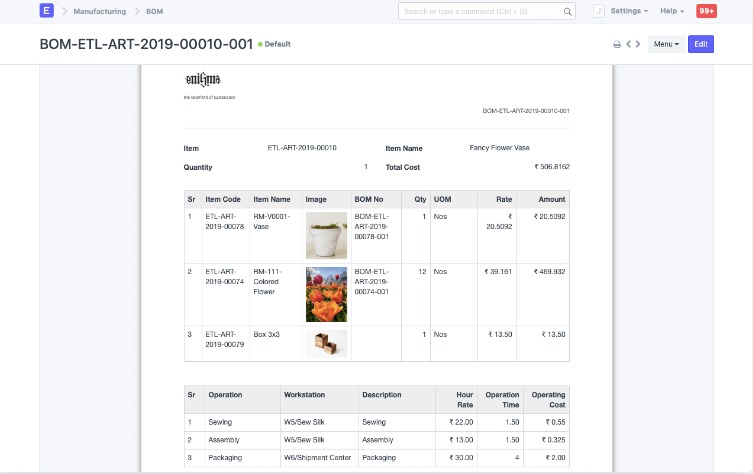

Easily handle the complexity of managing bills of material with seamless tracking of different product variants, specific parts, and revision control.

Always have the optimal inventory to support manufacturing and delivering products on time. With Just-in-time (JIT) delivery, minimize the inventory storage costs and order-to-cash cycle.

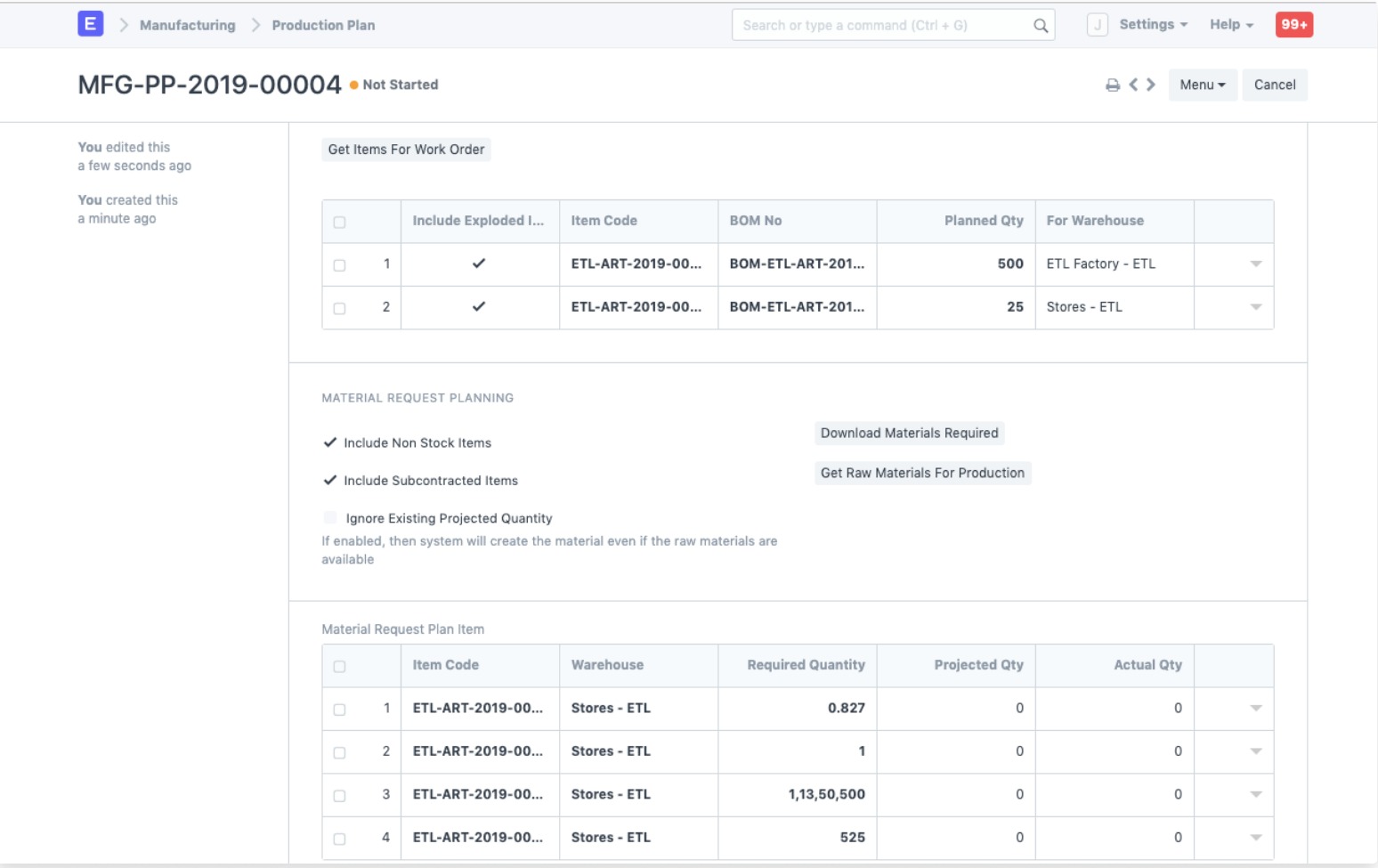

Plan for production with insight into the material, equipment, and labor requirements and dynamically reschedule production with changes in factors that might influence output.

Manufacturing essentials

Bring in

the simplicity of ERPNext  for discrete manufacturing.

for discrete manufacturing.

Inventory and supply chain management

Know your inventory needs. Streamline your supplies.

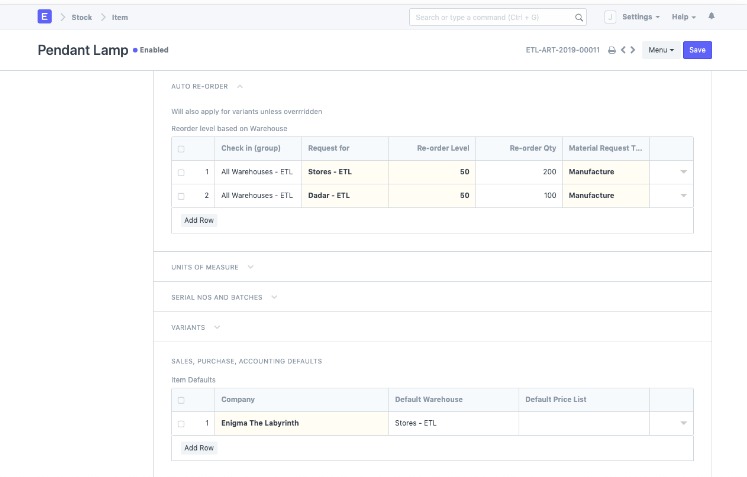

Track your inventory in real time. Easily record incoming and outgoing inventory by scanning barcodes with smartphones or handheld barcode scanners. Transfer stock between warehouses or deliver materials to the production department. Set reorder points and restock when needed. Save vendor contacts, automate vendor performance evaluation, and manage price discounts, promotions, and invoicing. See reports like inventory aging, vendor payments, sales, inventory valuation, and more.

Production management

Execute plans and control output.

Track plant floor performance with real-time data on issue materials, production, and downtime. Check schedules, sub-contracted job status, and floor capacity, and avoid obstacles before they occur. Generate sales orders, manage routing, schedule work orders, do product costing, and fulfill orders.

Quality control

Meet compliances. Ensure the highest quality.

Define control points and have regular inspections at the warehouse and production level, and do QC while receiving products from suppliers. Define specific attribute values for each review, capture analysis methods, and suggest lot/item changes based on the quality clearance report. Have end-to-end traceability for faster audits and compliance.

Integrate with

other useful  tools

tools

Use Dexciss ERP, built on ERPNext, with tools that make your operations more seamless and your growth more powerful.

FAQs

Most asked questions

Discrete manufacturing is the manufacturing of products using distinct items that can be easily counted and touched. Examples: automobiles, smartphones, furniture, etc.

Discrete manufacturing uses individual items like nuts, bolts, brackets, wires, and more to manufacture finished goods like toys, cars, etc. Process manufacturing uses formulas and recipes to make finished products like medicines, soft drinks, and more.

These seven features are a must-have for discrete manufacturing ERP.

Dexciss ERP is on cloud.

We provide support on chat and through tickets. See our support policy for more information.

The number of users or employees you can create is mentioned in the plan you select. You can always move to the next available option.